If you’ve ever dreamed of building a mid-drive e-bike that pulls like a dirt bike, you’ve probably wondered whether a planetary gear hub could survive the torque. Riders who want simplicity-a single gear or ultra-strong internal hub-face one big question: how much torque can the hub really handle? This article breaks down real product choices, shows how to calculate safe torque limits, and helps you decide when to go DIY, lock an internal gear, or switch to a motorcycle-grade hub. The goal: keep your drivetrain alive while putting serious power to the ground.

Start with What’s Proven – Planetary Hubs That Can Handle Power

Before sketching custom designs, look at what’s already built to take e-motor punishment. Modern internal gear hubs (IGHs) aren’t all fragile; some were purpose-designed for mid-drive systems and can take hundreds of newton-meters of torque when used within spec.

A few key production models already meet or exceed typical mid-drive torque demands, provided you respect input limits and external gearing ratios. Below are the most credible options.

Recommended High-Torque Planetary Hubs

| Hub Model | Gear Range / Type | Max Input Torque | Axle / Spacing | Notes |

|---|---|---|---|---|

| 3X3 NINE | 9-speed / 554% | 250 Nm | QR135 / 12×142 / 12×148 | Exceptional torque tolerance, sealed oil system, supports belt or chain; ideal for heavy cargo and powerful mid-drives. |

| Rohloff Speedhub 14 | 14-speed / 526% | 130 Nm | Multiple standards | Benchmark reliability, proven in expedition bikes; compatible with E-14 electronic shift that coordinates torque cut during gear changes. |

| Shimano Inter-5e | 5-speed / 263% | ~100 Nm (rated for e-bike assist) | Several axle options | Compact, commuter-friendly hub optimized for mid-torque systems, but must follow Shimano’s torque and gear-ratio charts. |

Takeaway:If you need raw durability, the 3X3 NINE is top-tier. For balanced longevity and proven support, Rohloff remains the gold standard. For affordable commuting, Inter-5e works-but only if torque is tamed through external gearing.

Recommended: The Tiny E-Bikes That Public Transit Actually Loves: Your Guide to Folding Commuter Models

Why “Motor Torque” Alone Misleads You

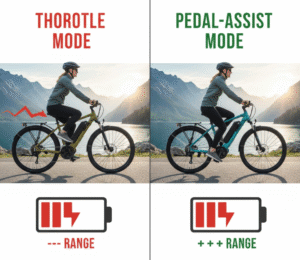

You might think “my motor is only 160 Nm, that’s fine.” But what reaches the hub is multiplied by your chainring-to-sprocket ratio and any intermediate gear stage. That means a seemingly mild setup can easily triple or quadruple hub torque-and break things silently until it’s too late.

When calculating safe torque, always translate crank torque into hub input torque. The equation below clarifies how much stress actually lands on your hub.

The Practical Torque Formula

Use this quick calculation for any drivetrain: Thub_in=(Tmotor+Trider)×ZfrontZrear×iinternalT_{\text{hub\_in}} = (T_{\text{motor}} + T_{\text{rider}}) \times \frac{Z_{\text{front}}}{Z_{\text{rear}}} \times i_{\text{internal}}Thub_in=(Tmotor+Trider)×ZrearZfront×iinternal

Where:

- TmotorT_{\text{motor}}Tmotor = peak torque at the crankshaft (from spec sheet)

- TriderT_{\text{rider}}Trider = estimated human torque (~30-50 Nm at sprint)

- Zfront/ZrearZ_{\text{front}}/Z_{\text{rear}}Zfront/Zrear = chainring ÷ rear sprocket teeth count

- iinternali_{\text{internal}}iinternal = gear ratio inside the hub (1.0 for direct drive)

You stay safe if: Thub_in≤Tlimit (hub)T_{\text{hub\_in}} \le T_{\text{limit (hub)}}Thub_in≤Tlimit (hub)

Quick 30-Second Example

Suppose you use a Bafang Ultra mid-drive rated 160 Nm peak plus 40 Nm rider torque.Your gearing is 38T : 22T → ratio = 1.73.Using a Rohloff in its 1 : 1 gear: (160+40)×1.73≈345Nm(160 + 40) \times 1.73 ≈ 345 Nm(160+40)×1.73≈345Nm

That’s nearly 3× over Rohloff’s 130 Nm input limit. The same motor on a 3X3 NINE (250 Nm limit) would still exceed spec unless you reduce chain ratio or electronically limit torque. Now you see why torque math matters before spending $1,500 on a hub.

Recommended: E-Bike Hydraulic Brake Problems: Why Your Lever Feels Soft and How to Fix It

Three Practical Paths – DIY, Locked Gear, or Dual-Stage Drive

Not every builder wants to buy a $1,500 Rohloff. Some chase a single-speed, planetary reduction hub-essentially a “mechanical torque multiplier.” Each path has pros, costs, and mechanical pitfalls.

Option 1 – Build a Single-Speed Planetary

A custom 3:1-6:1 reduction looks appealing: compact, quiet, and theoretically bomb-proof. But once you model real loads, you’ll find new problems-needle-bearing size, gear face pressure, axial loads from helical teeth, and the challenge of keeping everything concentric in a 75 mm shell. Small misalignments eat bearings fast. Even perfect design needs heat-treated steel gears and hardened races.

Checklist for DIY builders:

- Use case-hardened steel gears, not aluminum.

- Apply needle rollers or angular-contact bearings on both sun and planet shafts.

- Design for at least 1.5× expected torque margin (safety factor).

- Provide oil bath lubrication and heat venting; avoid dry grease systems.

- Expect iterative machining-prototyping rarely works first try.

Option 2 – Lock an Existing IGH into One “Strong” Gear

This hybrid path welds or pins one internal ratio permanently engaged. It saves design time and leverages proven gear geometry. The downside is irreversible modification, voided warranty, and potential thermal overload during continuous high-torque use-most IGHs rely on shifting cycles to distribute wear and circulate lubricant.

Practical advice:

- Choose the hub’s direct 1:1 gear as your locked stage-it bears the least compound load.

- Fill with high-viscosity synthetic gear oil (80W-90 or per manufacturer spec).

- Monitor case temperature during long climbs; add fins or vents if it exceeds 80 °C.

Option 3 – Add a Jackshaft or Dual-Stage Reduction

Instead of torturing the hub, shift heavy reduction earlier in the drivetrain. A small intermediate shaft can drop ratio 2-3× before power hits the hub. The result: moderate hub torque, adjustable gearing, and serviceable chainlines.

Pros: Modular, uses standard bicycle parts, easier torque tuning.Cons: Extra chain, efficiency loss (~2-3%), alignment complexity.Still, it’s the most reliable route for extreme setups (cargo, off-road, or >150 Nm motors).

Recommended: How to Fix Handlebars That Are Too Close to the Front Wheel

Frame and Axle Strength – Where Failures Start

Even if the hub survives, the frame often doesn’t. Under high torque, the first failure point is usually the dropout slot twisting forward, followed by stripped freewheel threads or bent sprockets. These issues escalate when using open dropouts and thin stays.

Axle Type and Torque Anchoring

For mid-drive power above 100 Nm, a 12 mm thru-axle or solid axle with keyed torque plates is essential. The hub shell alone can’t stop rotation; torque must be transferred into the frame through properly clamped torque arms. Both 3X3 and Rohloff offer thru-axle options that simplify this.

Minimum structural recommendations:

- Always fit dual torque arms or manufacturer-supplied plates.

- Keep dropout faces parallel and torque bolts to spec (20-25 Nm).

- Avoid aluminum dropouts unless they use steel inserts.

Lubrication and Heat Management

High torque at low speed generates heat. Oil-bath hubs manage this better than grease-filled ones. Check and replace gear oil every 3,000-5,000 km for daily riders, or sooner after heavy climbs or water crossings. Always refill to manufacturer’s fill line-over-filling foams oil and raises pressure, risking seal leaks.

Electronic Torque Control

When using electronic shifting systems such as Rohloff E-14, integrate them with your motor controller. These systems momentarily cut motor power (<300 ms) during shifts, reducing stress on gear faces and extending lifespan. Even without E-14, configure your controller for a short torque-reduction signal triggered by the shift sensor wire.

Recommended: Top Easy-Install 20-Inch Front Hub Motor Kits

Quick Torque Safety Checklist

Before final assembly, run through this torque sanity list:

- Verify motor peak torque and add estimated rider torque.

- Confirm front/rear sprocket ratio and hub gear ratio.

- Compute hub input torque using the formula above.

- Compare to manufacturer’s published maximum input torque.

- Respect minimum external ratio limits (e.g., Rohloff’s 2.5:1 chain ratio).

- If torque exceeds limit → reduce chainring size, enlarge rear sprocket, or limit controller current.

- Inspect dropout, axle, and torque arms before each season.

- Replace hub oil regularly (every 3-5 k km).

Following this procedure turns a risky build into a predictable, maintainable drivetrain.

FAQ

I just want a single-speed planetary hub that won’t explode under mid-drive torque. What exists?

Right now, 3X3 NINE is the strongest off-the-shelf IGH, tested for 250 Nm input. Locking one of its higher ratios or using direct-drive mode gives a near-“single-gear” feel while keeping oil cooling and sealed bearings intact. Cheaper IGHs may survive under throttle-limited systems, but not full-power mid-drives.

If I need a 6:1-12:1 total reduction, should I modify an IGH or add a jackshaft?

Use a jackshaft or secondary chain reduction. Let the IGH handle moderate torque and speed changes, not massive reduction. This keeps efficiency higher and maintenance easier. Modifying IGHs is risky and non-reversible.

Where does a frame usually fail under huge torque?

The dropouts twist, threads strip, and sprockets deform first. Upgrade to thru-axle, steel inserts, and dual torque arms. Treat the rear triangle as a torque-bearing structure, not just a mount point.

Putting It All Together – Design Once, Ride Long

Building a high-torque mid-drive e-bike isn’t about brute strength; it’s about controlled stress. When the drivetrain is matched-hub torque within limit, frame reinforced, oil changed on schedule-you get years of silent, reliable power. Riders who skip the math end up with cracked dropouts and seized hubs. Those who calculate, check ratios, and respect limits ride farther, faster, and safer.

Maintenance summary:

- Oil change interval: every 3-5 k km or annually.

- Torque-arm inspection: every 1 k km or monthly for heavy use.

- Chain tension check: every 500 km.These small steps keep the entire system stress-balanced.