Help! My Old-School E-Ride Just Fainted Under Pressure!

We’ve all been there: you finally get that awesome DIY electric project running, everything is smooth, you’re cruising past the neighbors, and then… poof. The power vanishes. Your motor goes from a happy hum to complete silence the moment you ask it to actually work.

This isn’t a ghost in the machine; it’s a common, infuriating issue, especially with custom builds or older electric vehicles (EVs) like the one we’re discussing today: a beloved, vintage electric quadricycle sporting a classic Crystalyte 408 hub motor and a venerable CT3625 controller.

The symptoms are crystal clear, yet utterly confusing:

- Cruising is Great: When the vehicle is first powered up, it runs fine.

- The Snub: When the battery drains slightly (say, from 45.7V down to 42.7V on a 36V system), the motor shuts off completely the instant a load is applied (i.e., when you try to move from a standstill or accelerate). The throttle’s “Power On” light goes dark.

- The Reboot Trick: Release the throttle, twist it again, and the power comes back on… until you try to move again.

- The “Flying” Test: Crucially, if you lift the drive wheel off the ground (empty load), the motor spins happily, even with a low battery (down to 37.6V!).

This tells us a very specific story: the components can handle the voltage, but they can’t handle the current surge required to move a heavy load. It’s time to play detective and figure out who the main suspect is.

Recommended: Fix Your Electric Bike Controller Not Working | Troubleshooting Tips

Is My Brand New Battery Just a Drama Queen?

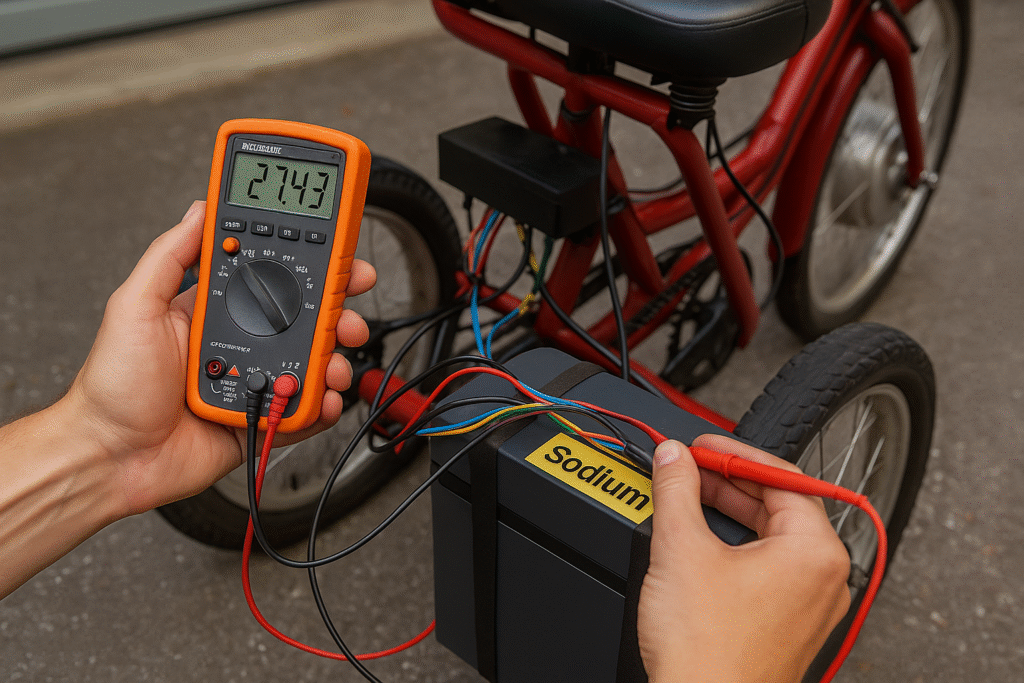

When troubleshooting an old system with a new component, you must immediately suspect the new part-even if it seems the least likely culprit. In our quadricycle’s case, the new addition is a large, custom-built 36V 45Ah Sodium battery.

Why would a brand-new, powerful battery be the weak link? The answer lies in the silent guardian of modern cells: the Battery Management System (BMS).

The BMS has one job: protect the cells. It does this by aggressively cutting power if it detects two things: Over-Current (Too many amps being pulled) or Under-Voltage (The voltage drops too low).

When you start an e-bike from a standstill, the motor pulls a massive surge of current (Amps) to overcome inertia. This massive current draw, even if momentary, causes a rapid, temporary dip in the battery’s voltage-a phenomenon called Voltage Sag.

The Big Question: Is the new battery’s BMS the sensitive culprit?

Recommended: What Kind of Electric Bike Should Seniors Ride? A Complete Guide

Our First Core Question (The Troubleshooting Priority)

“Ugh, so everyone thinks the BMS on my new battery is the ‘Drama Queen’ that keeps shutting things down? Well, for a beginner like me who can’t mess with the controller’s guts, is there a simple, direct fix to stop my ride from fainting every time I hit the throttle?”

Expert Perspective: Yes, this is the most likely culprit. The brand-new BMS, designed for maximum cell protection, is probably set to trip at a current level slightly too low for the old, inefficient, high-torque Crystalyte motor to start from a dead stop.

Simple Solutions to Test (The First Steps):

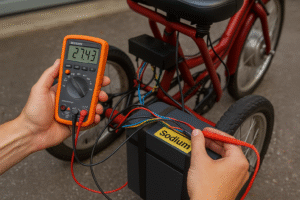

- Check Connections: Use a multimeter to measure the voltage while attempting to accelerate. If the voltage at the controller’s input drops dramatically (below 30V for a 36V system) right before it cuts out, it confirms severe voltage sag.

- Give it a Kick: Try starting the quadricycle with a brief push or kick-start to reduce the initial current demand. If this works, the problem is 100% the BMS’s Over-Current Protection (OCP).

- BMS Reset: Some newer BMS units can be reset or have parameters adjusted via Bluetooth, but a custom sodium battery build might not have this feature. The easiest reset is often simply plugging in the charger for a moment.

My Controller is a Dinosaur! What Should I Buy if the Old Guy Croaks?

While we suspect the battery’s BMS, sometimes these old controllers (like the 36V 25A CT3625) can simply be too worn out or inefficient to handle modern battery power delivery. Years of high-amp bursts can degrade the internal MOSFETs or capacitors. If the simple kick-start test doesn’t resolve the issue, you must prepare for a component replacement.

This leads us to the next, critical step for any DIY enthusiast: the replacement strategy.

Our Second Core Question (The Compatibility Challenge)

“My whole system is a total ‘Dinosaur,’ including the connectors! If I have to ditch this old, finicky controller, which basic, reliable, and highly compatible new 36V controller would the ‘Tech Wizards’ recommend to work smoothly with my classic hub motor? And please, are adapters even available to match a new controller’s plugs to my ancient motor’s wiring?”

The Modern Controller Solution:

When upgrading a vintage system, the primary goal is reliability and ease of use. Look for:

- A Sine Wave Controller: These are smoother and often more efficient than the older square-wave controllers, reducing stress on both the motor and the battery.

- Voltage and Amperage Match: Stick to a 36V controller, but consider one with slightly higher current limits, say 30A (rather than the old 25A). This extra buffer might prevent the new controller from tripping itself, especially when paired with a high-capacity 45Ah battery.

- A “Smart” Controller (Optional but Recommended): Look for controllers that are “self-learning” or support Hall Sensor and Sensorless modes. The Crystalyte 408 is a sensored motor, but having the flexibility is helpful.

The Connector Conundrum:

The reality is that old connectors are often proprietary and simply don’t match modern standards (like the ubiquitous Anderson Powerpole for battery connection or standard JST/Higo plugs for signaling).

The answer is Yes and No:

- No, Direct Adapters are Rare: You usually won’t find an off-the-shelf adapter that goes from “Vintage Crystalyte Plug A” to “Modern Controller Plug B.”

- Yes, DIY Adapting is Necessary: The standard procedure for reviving these older bikes is cutting and splicing. You will need to carefully match the phase wires (the three thick motor wires) and the Hall sensor wires (the five thinner wires) from the new controller to the old motor, using solder and marine-grade heat shrink for a durable, weather-proof connection. This is an essential skill for working on older electric vehicles.

Recommended: Electric Bike Bearing Troubleshooting Tips

What’s the Deal with This ‘Sodium’ Battery Anyway?

The final, and most intriguing, variable in this equation is the power source itself. While Lithium-ion is dominant, the owner specifically mentioned using a new Sodium battery. Sodium-ion battery technology (Na-ion) is gaining traction as a potential low-cost, sustainable alternative to Lithium.

But does this unique chemistry contribute to the problem?

Our Third Core Question (The Chemistry Challenge)

“I’m using a new, custom-built ‘Sodium Battery’-that sounds pretty advanced! Does this particular chemistry have a different ‘temperament’ than regular Lithium batteries? Specifically, is its performance under heavy load or its momentary voltage drop characteristic more likely to trigger an over-protective cut-off from the controller or BMS?”

Sodium-ion Performance vs. Lithium:

Currently, one of the main trade-offs of commercialized sodium-ion batteries compared to high-performance lithium-ion is Power Density (the ability to deliver high current quickly) and Energy Density (capacity per volume/weight).

- Higher Internal Resistance: Early Na-ion formulations can have slightly higher internal resistance compared to high-drain lithium-ion cells (like those used in power tools or high-performance e-bikes).

- The Impact on Sag: Higher internal resistance means that when a large current spike is demanded (like starting the quadricycle), the voltage will sag more dramatically and more rapidly than a comparable high-end lithium battery.

- The Verdict: If the new Na-ion battery pack’s BMS is tuned for a moderate C-rate (discharge rate) or if the cells simply can’t deliver the instantaneous 50-60A surge the motor needs to start, the voltage will plummet faster than the BMS’s Low Voltage Cutoff (LVC) threshold. This strongly supports the diagnosis that the BMS protection is being tripped by voltage sag under load.

Recommended: Quick Guide to Unlocking E-Bike Speed Limits

The Final Verdict: How to Get Your Wheels Rolling Again

The mystery of the “fainting motor” almost certainly comes down to a communication breakdown between the old motor/controller’s demands and the new battery’s protection settings.

Your Recommended Action Plan (In Order):

- Confirm the BMS: Perform the “Kick-Start Test.” If the vehicle starts fine after a slight push, the BMS is the trip switch.

- Measure Voltage Under Load: Get a voltmeter on the main power lines and verify the voltage sag during the cutoff. This provides definitive proof.

- Contact the Battery Builder: Since this is a custom Sodium pack, the most direct solution is to ask the manufacturer if the BMS’s Over-Current Protection (OCP) limit can be adjusted or if they can confirm the continuous and peak discharge rate of the cells. A 45Ah pack should, in theory, handle 25A continuous easily, but the peak startup current is the killer.

- Prepare for the Upgrade: If steps 1-3 fail, accept that the vintage controller is incompatible with the protection profile of the new battery. Purchase a modern, high-quality 36V controller (30A or higher) and be ready to manually match and splice the motor’s phase and Hall sensor wires.

Don’t give up on your magnificent, old-school electric quadricycle! With a little troubleshooting and possibly a wire snip or two, you’ll be back on the road, leaving those “mystery shutdowns” in the dust.