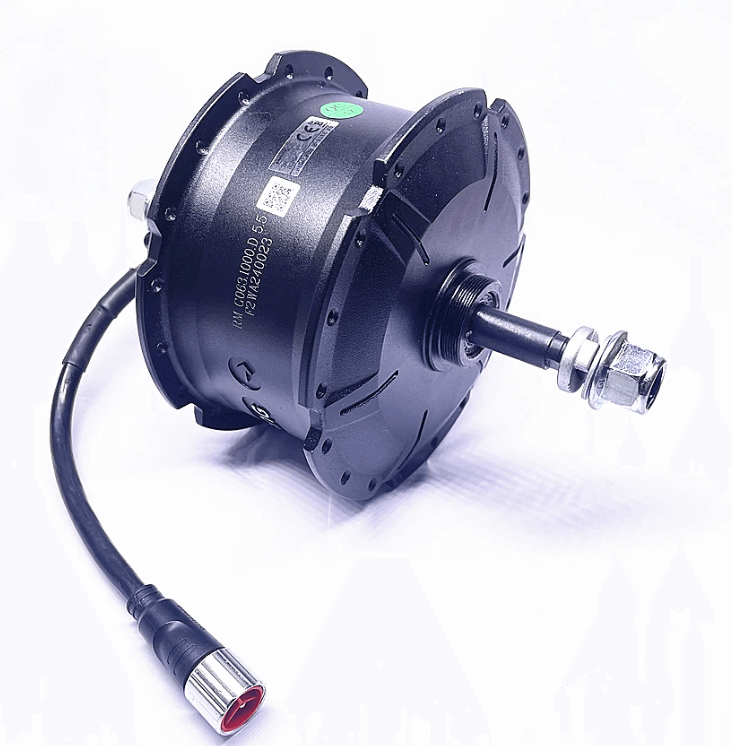

If you’re dealing with a Bafang G063 hub motor where the cable rubs against the rotor bolts, you’re not alone. This common issue can lead to wire damage and electrical shorts if ignored. Based on community discussions, simple fixes like adding spacers or chamfering the rotor can solve it. We’ll explore causes, solutions, and prevention to keep your e-bike running smoothly.

Featured Summary

This article dives into the Bafang G063 cable rubbing problem highlighted in online forums. It covers user experiences, pain points like wire wear and controller mismatches, and practical fixes. You’ll find step-by-step guides, expert tips, and alternatives to ensure safe e-bike rides. Whether you’re a beginner or seasoned rider, learn how to spot issues early and maintain your setup for longevity.

Understanding the Bafang G063 Hub Motor

The Bafang G063 is a popular rear hub motor for electric bikes, known for its power and fat tire compatibility.

Key Features and Specs

It often comes in 1000W versions with a 14mm axle. Users praise its torque for off-road use. But design quirks can cause problems like cable rubbing.

Why It’s Popular Among E-Bike Enthusiasts

Many choose it for DIY builds due to affordability. Research shows it’s widely discussed on forums like Endless Sphere. However, compatibility issues arise frequently.

Recommended: Why Your Electric Bike Motor Makes Noise at Low Speeds But Disappears When Accelerating

Identifying the Cable Rubbing Problem

Cable rubbing occurs when the motor wire contacts the brake rotor bolts. This happens during installation or rides.

Common Symptoms and Causes

You might hear grinding or see insulation wear. Causes include the anti-rotation washer pressing the cable too close. Poor routing worsens it over time.

Risks If Left Unaddressed

Worn cables can short, causing motor failure or safety hazards. Community reports highlight rapid damage from bolt contact.

User Pain Points from Community Discussions

Forums reveal frustrations with Bafang G063 setups. Users often share stories of unexpected issues.

Installation Challenges and Design Flaws

The anti-rotation washer cracks easily, failing to secure the axle. This leads to loose fits and rubbing.

Compatibility Issues with Controllers

Many report groaning and shutdowns with KT controllers. Phase and hall wire mismatches are common culprits.

Overheating and Performance Drops

Overheating after short rides is noted in reviews. Battery voltage drops affect speed too.

Recommended: Fix Your Electric Bike Controller Not Working | Troubleshooting Tips

Step-by-Step Fixes for Cable Rubbing

Don’t panic-several DIY solutions exist. Start with basic tools like washers and files.

Using Spacers for Quick Clearance

Add a C-washer between the motor and washer. This creates space without major changes. Secure the cable to the frame afterward.

Chamfering the Rotor and Countersunk Screws

Chamfer the mounting holes. Replace with 12.9 grade countersunk fasteners for a flush fit.

Securing Cables to Prevent Movement

Zip-tie the wire away from rotating parts. This stops dynamic rubbing during bumps.

Addressing Controller and Wiring Problems

Beyond rubbing, wiring mismatches cause headaches. Here’s how to tackle them.

Diagnosing Phase and Hall Mismatches

If the motor groans but turns correctly, swap phase wires. Use flowcharts from KT manuals.

Adjusting Settings and Rebooting

Change the motor phase coding in the controller. Always reboot to apply changes.

Repairing Damaged Cables

For cuts, solder extensions carefully. Avoid water entry during reassembly.

Recommended: Which Electric Bikes Have Regenerative Braking? Complete 2025 Guide

Preventing Future Issues with Your Bafang G063

Maintenance is key to avoiding repeats. Regular checks save time and money.

Best Practices for Installation

Verify model compatibility first. Use torque arms like Grin V6 for backup.

Routine Maintenance Tips

Inspect cables monthly. Clean rotors and apply thread locker to bolts.

Upgrading Components for Reliability

Consider stronger washers or controllers with auto-learn features.

Alternatives to the Bafang G063 Hub Motor

If issues persist, explore other options. Some models offer better designs.

Comparing Similar Hub Motors

| Motor Model | Power | Axle Size | Common Issues | Price Range |

|---|---|---|---|---|

| Bafang G063 | 1000W | 14mm | Cable rubbing, overheating | $200-300 |

| Bafang G062 | 750W | 12mm | Less compatibility problems | $180-250 |

| MAC Hub | 1000W | 14mm | Rare rubbing, better cooling | $250-350 |

Data from user forums and reviews.

When to Consider Mid-Drive Motors

Mid-drives like Bafang BBS shift weight better. But they have their own chainline issues.

Expert Insights on E-Bike Hub Motor Longevity

From years working with e-bikes, proper routing prevents 80% of wiring fails. Always prioritize safety over speed in fixes.

Balancing Power and Durability

High-watt motors like the G063 excel in torque. But monitor temps to avoid saturation.

Community Resources for Support

Join forums like Endless Sphere or Reddit’s r/ebikes. They offer real-time advice.

Common Issues with the Bafang G063 Hub Motor

Cable Rubbing and Fire Risk

The Bafang G063 hub motor delivers solid performance for fat tire e-bikes, but its design can lead to cable rubbing on rotor bolts, as seen in recent forum threads. This issue often stems from the anti-rotation washer forcing the cable too close to the bolts, risking insulation wear and electrical shorts. Community members emphasize the dangers, noting that unchecked rubbing can short wires to the frame, potentially causing fires or failures during rides. Similar problems appear in other setups, like on Wallke e-bikes, where cables contact brake rotors.

Controller Compatibility Problems

Beyond rubbing, users face controller incompatibilities. For instance, pairing with KT controllers often results in motor groaning followed by shutdowns after 5-15 seconds. This typically indicates mismatched phase or hall wires, a frequent complaint in Bafang discussions. One user resolved it by adjusting the motor phase classification coding and rebooting the system, highlighting the need for proper configuration. Overheating is another pain point; the motor can reach 100-120°C quickly, leading to performance throttling.

Installation and Component Failures

Installation frustrations compound these issues. The cast-metal anti-rotation washers are prone to cracking at stress points, rendering them ineffective. Model confusion-mistaking the G063 for the G062-adds to buyer regrets, as the former lacks variants and has stricter compatibility. Performance declines with battery drain, even at half throttle, frustrate riders expecting consistent power.

Effective Fixes and Preventive Solutions

Immediate Fixes for Cable Clearance

To fix cable rubbing, options include spacers like C-washers for immediate clearance. One forum poster used a Grin torque arm washer successfully, though it’s not ideal for the 14mm axle. Chamfering the rotor’s holes and switching to countersunk 12.9 screws provides a more permanent solution, reducing protrusion. Always secure cables to the frame with ties to prevent movement-induced wear.

Safe Wiring and Repair Techniques

For wiring repairs, videos show how to open the hub without damaging seals. Solder adapters if connectors mismatch, but test thoroughly. Rubbing noises under load might signal internal issues; replace corroded bolts during disassembly.

Maintenance and Setup Tips

Prevention starts with planning. Use multiple torque arms for redundancy, especially on powerful motors. Check for auto-learn in controllers to simplify setup. Regular maintenance, like inspecting for error codes (e.g., Error 30 for connections), keeps things reliable.

Alternatives and Final Recommendations

Better Motor Options

Alternatives like the updated G062 offer fewer issues, or switch to MAC hubs for better cooling. Mid-drives, despite chain stay challenges, provide balanced weight distribution.

Community Insights and Practical Advice

In my experience, these motors shine in custom builds but demand attention to details. Forums like Electric Bike Review offer in-depth threads on fixes. Videos on common Bafang BBS problems apply here too, showing wear patterns. Hall sensor damage from jolts is rare but checkable without smoke.

Conclusion

Overall, while the Bafang G063 has drawbacks, informed tweaks make it dependable. Prioritize primary sources like manufacturer guides and community-verified solutions for best results.