Featured Summary

Bleeding hydraulic e-bike brakes purges air and replaces old fluid so the system feels solid and stops predictably. Do it when the lever feels spongy, pulls to the bar, after hose/calliper/lever service, or as routine maintenance (commuters: yearly). A careful home mechanic needs 30-60 minutes per brake once set up; skill level: intermediate-not hard, but precision and cleanliness matter.

Results you’ll notice

- Firmer lever

- Consistent bite point

- Safer stopping on heavier e-bikes

What “Bleeding” Hydraulic Brakes Actually Does

Bleeding expels compressible air bubbles and degraded fluid, replacing it with fresh, bubble-free fluid. That restores a solid hydraulic column between your lever piston and caliper pistons, so pressure translates into pad clamping force with minimal delay.

Why air ruins braking performance (compressibility, spongy feel, long lever travel)

Air compresses; brake fluid doesn’t (not meaningfully). Even a few tiny bubbles act like little springs in the line:

- Spongy feel: the lever moves, but pressure builds slowly.

- Long lever travel: bite point wanders toward the bar.

- Heat fade: bubbles expand when hot, magnifying the problem.

E-bike specifics (heavier mass, longer hoses, heat/fade risk, brake-cutoff sensors)

E-bikes are heavier and often route longer hoses through frames and around motors. More mass + heat + hose length = more chances for microbubbles to hide and for fluid to degrade. Also mind brake-cutoff sensors-contamination or misalignment can cause false motor cut or no cut at all.

When to bleed (after mushy lever, lever pulls to bar, after hose/service, yearly on commuters)

- Symptoms: mushy/spongy lever, inconsistent bite, lever hits bar.

- After service: any time you open the system (new hose, fittings, caliper/lever rebuild).

- Intervals: e-bike commuters every 12 months (6-12 months if wet/steep); performance riders sooner or whenever feel degrades.

Recommended: Affordable Electric Bikes Under $1,000 at Walmart: Top Picks and Buying Guide

Safety First (Read Before You Start)

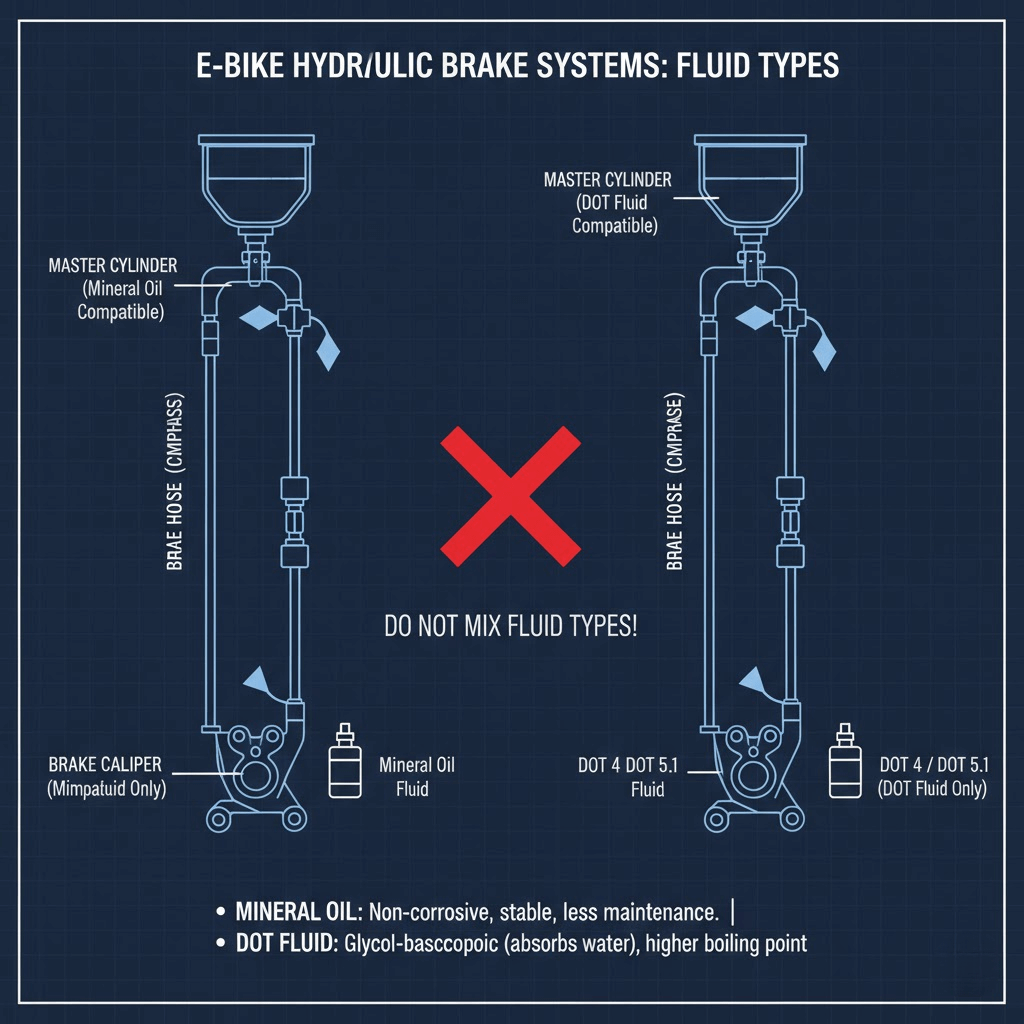

Mineral Oil vs DOT Fluid

Compatibility (high-level-confirm your exact model):

| Brand | Typical Fluid | Notes |

|---|---|---|

| Shimano | Mineral oil | Use a funnel at the lever. |

| Tektro/TRP | Mineral oil | Similar to Shimano flow. |

| Magura | Mineral oil (“Royal Blood”) | Unique fittings; delicate lever screws. |

| SRAM | DOT 4/5.1 (many models) | Two-syringe push-pull. SRAM DB8 uses mineral-confirm model. |

- Never mix fluids. Mineral vs DOT seals are different. Cross-contamination can swell/destroy seals and damage paint (DOT is aggressive).

- Label everything (funnels/syringes) to prevent mix-ups.

PPE & Work Area

- Nitrile gloves and eye protection.

- No open flame/heat near DOT.

- Protect rotors/pads with masks or clean cards/foil; one drop of fluid can ruin braking.

- Keep isopropyl alcohol (90%+) and lint-free rags ready.

Bike Setup

- Power off or remove the battery.

- Put the bike on a stable stand; level the bike.

- Secure bars; rotate the lever so its reservoir is level (critical for bubble release).

Recommended: Haven Electric Bike Review: Value, Specs & Real-World Ride Impressions

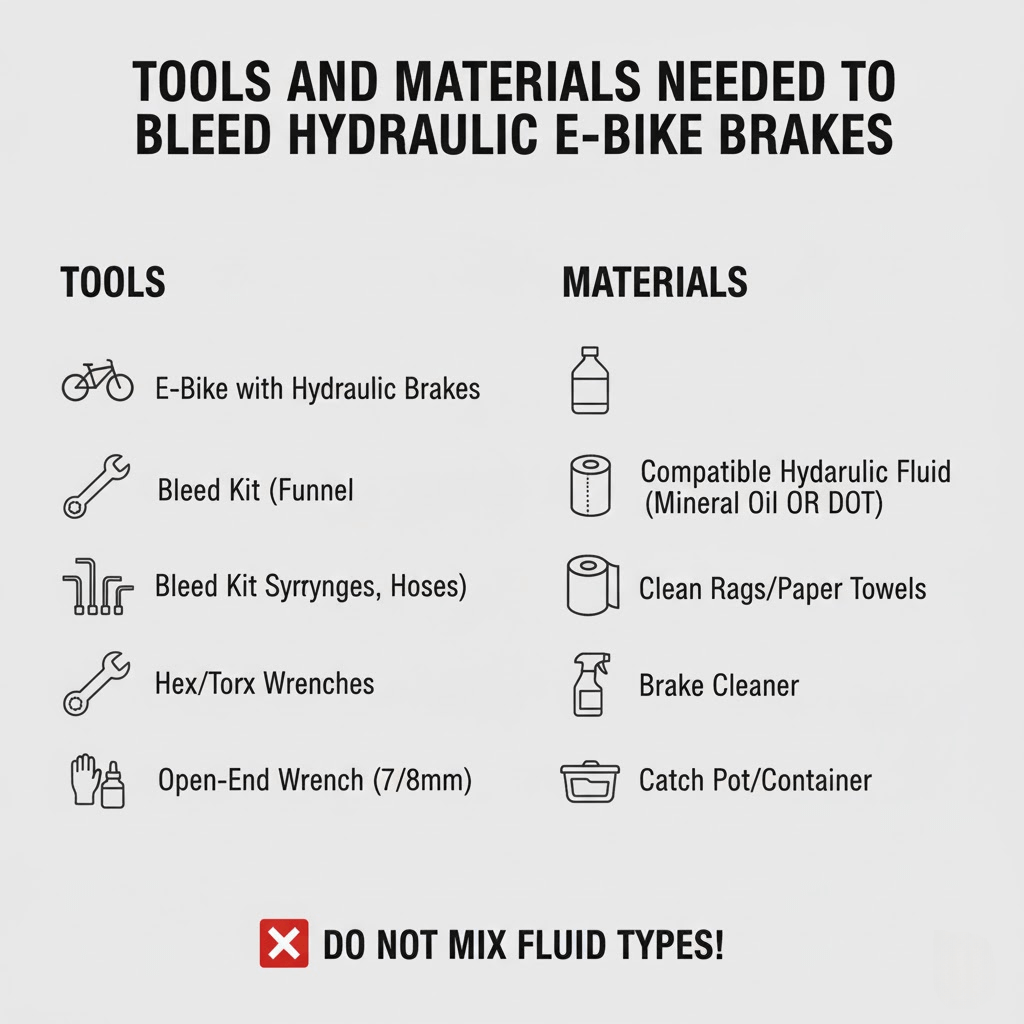

Tools & Materials Checklist

Universal

- Allen keys/Torx (usually T25 for rotor bolts).

- Clean, lint-free rags; isopropyl alcohol (90%+).

- Rotor/pad masks (cardboard/plastic shields).

- Bleed block (keeps pistons square).

- Zip ties/tape for hose management.

- Small flat driver or piston press (for pad removal/spacing).

Fluid & Kits by Brand

- Shimano/Tektro/Magura (mineral): correct mineral oil, lever funnel/cup + tube, lower tube for caliper.

- SRAM (DOT): DOT 4/5.1 as specified, two-syringe kit with good seals.

- Clear tubing, correct barbs/olives if you opened/shortened a hose.

- New crush washers for banjo bolts/bleed ports when required.

Optional but Helpful

- Torque wrench (lever clamp, caliper mount, rotor bolts).

- Funnel/cup stand at lever height.

- Magnetic tray for tiny screws.

- Dedicated brake piston press.

Pre-Checks to Avoid Wasting a Bleed

Inspect pads & rotors (glazing, contamination, thickness limits)

- Pads: if contaminated/glazed (squeal, shiny surface) or below wear limit, replace first.

- Rotors: check thickness (often 1.8-2.0 mm new; replace near 1.5 mm-confirm spec) and trueness.

Check for leaks (caliper/lever/banjo fittings, wetness/dirt accumulation)

Look for dampness around banjo fittings, lever piston boots, and caliper halves. Persistent wet/dust caking = likely leak-fix before bleeding.

Lever reach & bite-point settings (set neutral to diagnose accurately)

Set reach and (if present) bite-point adjusters to neutral/mid so you can judge improvements accurately.

Caliper alignment (centered over rotor, no rub)

Loosen mount bolts, squeeze lever, and tighten evenly to center. A rubbing caliper can mimic weak braking.

Recommended: Are Electric Bikes Available for Purchase on Temu?

Step-by-Step Bleed Procedure (Generic Method)

Callout: Top-Up/Lever-End vs Full System

- Top-Up/Lever-End (quick): for minor sponginess; purge small bubbles at the lever.

- Full System (thorough): when lines were opened, after component swaps, or if lever-end didn’t fix it.

Step 1 – Prepare the System

- Remove the wheel and pads; install a bleed block.

- Mask the rotor area/frame.

- Rotate/level the lever reservoir; remove reservoir cap/plug per brand.

Step 2 – Set Up Your Lines

- Mineral systems (Shimano/Tektro/Magura): install funnel/cup at the lever; a short tube on caliper bleed port.

- SRAM DOT: attach upper syringe at lever and lower syringe at caliper. Ensure airtight connections.

Step 3 – Add Fresh Fluid

- Pre-fill the lower syringe (or funnel) with fresh, correct fluid.

- Tap the syringe/tubing to float bubbles up; expel air from the syringe tip.

- Keep the plunger lightly loaded to prevent back-suction.

Step 4 – Push-Pull Exchange

- Crack the caliper bleed screw open.

- Gently push fluid from caliper upward. Tap hose runs, caliper body, and lever to dislodge microbubbles.

- For SRAM, cycle push-pull between syringes as instructed to trap and remove stubborn bubbles.

Step 5 – Lever Feather & Bubble Release

- Slowly squeeze/release the lever 5-10 times while observing bubbles at the funnel/upper syringe.

- Pause; tap lines and lightly flick the caliper and lever to free hidden bubbles.

Step 6 – Seal the System

- Close the caliper port to spec (snug, then torque-see table below).

- Remove the lower tube/syringe.

- Top off the lever reservoir/funnel to the correct level; install cap/plug while keeping the reservoir level.

Step 7 – Clean & Reassemble

- Alcohol-wipe lever, caliper, frame, and your hands.

- Reinstall pads and wheel.

- Re-center the caliper; set lever reach.

Step 8 – Bed-In & Test

- In a safe area, do 10-20 firm stops from moderate speed to bed pads.

- Check: consistent bite point, one-finger power, no leaks or rub.

Brand-Specific Mini-Procedures (Quick References)

Shimano/Tektro (Mineral Oil + Funnel)

- Use the lever-end funnel; push fresh oil from caliper up.

- Gotchas: overfilling the funnel, lever not perfectly level, missing tiny black O-ring at the lever screw.

Magura

- Royal Blood mineral oil.

- Delicate lever screws-use perfect-fit tools and light torque.

- Plastic fittings can crack if overtightened; stop at “snug + a touch.”

SRAM (DOT + Two-Syringe)

- Push-pull cycle is essential; keep syringes upright to trap bubbles.

- SwingLink levers: follow the specific lever-bleed step to purge the tiny bladder.

- DOT + paint: wipe any spills immediately with alcohol; DOT can strip finishes.

Common Mistakes & How to Avoid Them

Contaminated pads/rotor (symptoms: squeal, fade; fix: replace pads, deep-clean rotor)

If pads were soaked, replace. Clean rotors with isopropyl (no oily cleaners). Re-bed pads.

Trapped microbubbles (tap lines, rotate caliper, lever position importance)

Keep the lever reservoir level, tap frequently, and slow your push. Sometimes holding the bike at a slight angle helps bubbles migrate.

Wrong fluid (seal swell or failure-flush immediately if misfilled)

If you misfilled, stop. Disassemble and flush completely with the correct fluid; inspect/replace seals.

Over-tightened/under-torqued bleed screws (stripped ports, leaks)

Use correct bits and moderate torque. If a port weeps after snugging, replace the crush washer or fitting.

Troubleshooting After a Bleed

Lever still soft

- Re-bleed with slower pushes.

- Orient caliper/lever to encourage bubbles up.

- Inspect for micro-leaks at banjos/ports.

- Check for sticky pistons-clean and reset with a bleed block.

Lever firm but weak power

- Pad glazing/compound mismatch.

- Rotor too thin or contaminated.

- You skipped bed-in-redo the process.

One brake stronger than the other

- Pad mismatch side to side, or one caliper’s pistons lagging.

- Hose length/loops can change feel; ensure similar setups where possible.

- Clean, lube seals lightly (per brand), and re-center.

Intermittent bite point

- Heat expansion on long descents-consider bigger rotors/metallic pads.

- Air at lever bladder-repeat lever-end purge.

- Master cylinder seal could be failing-inspect/rebuild/replace.

E-Bike-Specific Pro Tips

Heavier Loads & Long Descents

- Size up rotors (180-203 mm) and consider sintered/metallic pads.

- Refresh fluid more often; heat cycles age it faster.

Hose Routing on E-Bikes

- Avoid tight bends around the motor; secure away from wiring and brake-cutoff sensors.

- Ensure sensors trigger reliably after reassembly.

Maintenance Interval

- High-mileage commuters: bleed every 6-12 months or 2-3k miles.

- Cargo/towing/downhill riders: check more frequently.

When to Replace, Not Bleed

Damaged hose/banjo/crushed olives

If you see cracks, kinks, or crushed olives, replace components-bleeding won’t cure a mechanical fault.

Master cylinder or caliper seal wear

Persistent weeping, lever creeping under steady pressure-rebuild/replace.

Rebuild kits vs new components (cost/risk/time matrix)

- Rebuild: cheaper, more time, requires care.

- Replace: faster, pricier, often more reliable for daily commuters.

Environmental & Disposal Notes

Dispose fluids responsibly (DOT = hazardous; mineral oil = recycle per local rules)

- DOT is hazardous waste-use approved disposal.

- Mineral oil: recycle per local guidelines (never dump).

Spill cleanup (alcohol, no water on DOT spills near paint)

- Wipe immediately with isopropyl.

- Keep fluid off tires, pads, rotors, paint.

Mini Reference Tables

Fluid Compatibility by Brand/Model (high-level; remind to check manual)

- Shimano/Tektro/TRP: Mineral oil

- Magura: Mineral oil (“Royal Blood”)

- SRAM: DOT 4/5.1 on many models; DB8 = mineral → always confirm your exact brake

Common Torque Specs (ranges; check your manual)

- Rotor bolts (T25): ~6 Nm

- Caliper mount bolts: 6-8 Nm (post mount often ~8 Nm)

- Lever clamp bolts: 4-6 Nm

- Bleed port screws: snug/light torque with fresh washer or O-ring

FAQs

How do I know my e-bike brakes need bleeding?

Spongy feel, bite point moves toward the bar, or after any hose/component service.

Can I bleed only the lever end to fix a soft feel?

Yes for minor air near the lever; for persistent issues, do a full system bleed.

Mineral oil vs DOT-what’s safer for home mechanics?

Mineral is gentler on paint/skin. DOT works great but demands stricter handling. Always use what your brakes require.

Why did my lever go to the bar after a crash or pad change?

Air entered or pistons shifted. Install a bleed block and re-bleed; re-center the caliper.

How often should I bleed e-bike brakes if I commute daily?

Every 6-12 months (sooner for heavy loads/steep hills or if feel degrades).